Efficient solid-liquid-separation can be achieved effectively with filter presses. In this way, the lowest residual moisture values are obtained in the filter cake.

It is irrelevant, if the mixture to be filtered is a suspension of the food industry or waste water. the operation is the same.

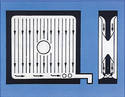

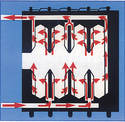

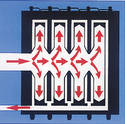

In simplified terms, a filter press is composed of a solid frame, a closure and a movable plate pack with filter cloths. This plate pack is compressed like a “Vice” The. By means of a media pum, a suspension is sent into the labyrinth composed of filter plates covered with filter cloths “During” the flow of the suspension. the solids are retained in the chambers. The liquid can exit the chambers through the filter cloths, is collected and removed. Due to the fluid pressure, the solids are pressed and evacuated into the cake container when the chambers are full.

With increasing size of the filter press and an increasing degree of automation, other components such as automatic plate shifting, optical safety barriers, on-line filter cloth cleaning equipment etc. can be added.